Saddle stitch staplers, or saddle staplers, are bookbinding tools that people use to insert staples into the spines of folded prints, such as booklets, manuals, brochures, and catalogues. Standard staplers are typically too short for these printed formats. A saddle stapler is longer in length and has a distinguished “V-shaped” saddle that helps the user align the central fold of the printed matter to where it requires stapling. A manual saddle stapler works best for customized booklets, but digital production printers often have a feature for saddle stitch units that automatically fold and staple printed materials for you.

Saddle stitching, commonly referred to simply as stitching in the printed industry, earned its name from process of draping collated sheets over a saddle shaped apparatus during the stapling process. Saddle stitching refers to a popular book binding method that uses folded sheets gathered inside one another and stapled through the fold line with wire staples. The staples get inserted through the folded crease from the outside and cinched between the centermost pages. Two staples is the standard amount for booklet binding, unless it’s a larger booklet that requires more staples along the spine. The following instructions and guidelines will help you learn how to use a saddle stapler for booklet binding and show you how it impacts a folded printed project.

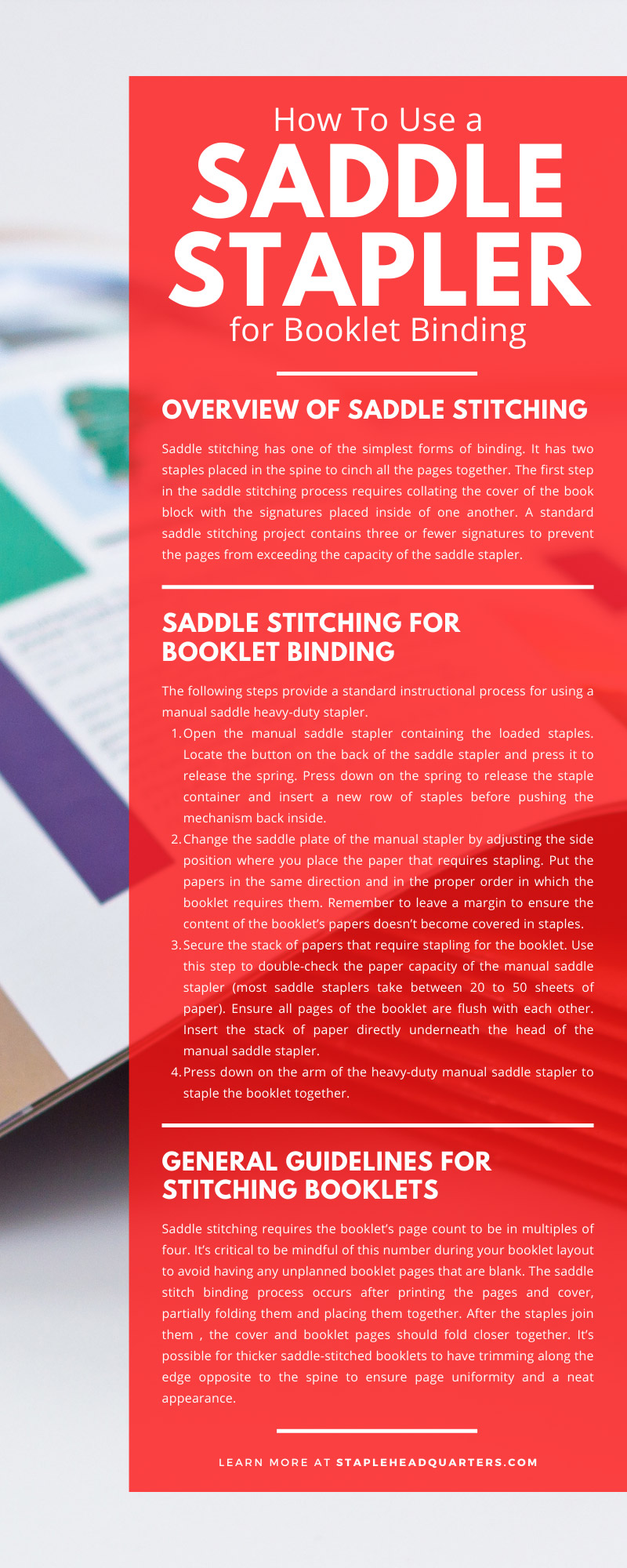

Overview of Saddle Stitching

Saddle stitching has one of the simplest forms of binding. It has two staples placed in the spine to cinch all the pages together. The first step in the saddle stitching process requires collating the cover of the book block with the signatures placed inside of one another. A standard saddle stitching project contains three or fewer signatures to prevent the pages from exceeding the capacity of the saddle stapler.

Afterwards, the collated pages become stapled using a manual saddle stapler or placed through a stitching machine. When using a stitching machine, the pages drape across each side of the “saddle” belt that operates across the machine. The V-shaped belt helps align the pages at the central fold to ensure symmetrical binding. The stapler moves down the line of the central fold and inserts the staples. The finished product undergoes trimming to reach its final size and completes the saddle-stitched project.

Saddle Stitching for Booklet Binding

It’s important to remember that saddle staplers come in both manual and electric forms. Manual saddle staplers come in various designs and cost less than an electric saddle stapler. A manual saddle stapler can install as many staples through paper as the electric model but requires more physical strength from the person using it. Manual saddle staplers suit smaller projects with infrequent use.

The following steps provide a standard instructional process for using a manual saddle heavy-duty stapler.

- Open the manual saddle stapler containing the loaded staples. Locate the button on the back of the saddle stapler and press it to release the spring. Press down on the spring to release the staple container and insert a new row of staples before pushing the mechanism back inside.

- Change the saddle plate of the manual stapler by adjusting the side position where you place the paper that requires stapling. Put the papers in the same direction and in the proper order in which the booklet requires them. Remember to leave a margin to ensure the content of the booklet’s papers doesn’t become covered in staples.

- Secure the stack of papers that require stapling for the booklet. Use this step to double-check the paper capacity of the manual saddle stapler (most saddle staplers take between 20 to 50 sheets of paper). Ensure all pages of the booklet are flush with each other. Insert the stack of paper directly underneath the head of the manual saddle stapler.

- Press down on the arm of the heavy-duty manual saddle stapler to staple the booklet together.

You should note that electric saddle staplers suit larger projects because they don’t require manual labor to complete the job. Electric models include a motor to drive staples through paper without exerted force. Manual saddle staplers also don’t have the ability to load different lengths of staples or drive staples through larger stacks of paper.

General Guidelines for Stitching Booklets

Saddle stitching requires the booklet’s page count to be in multiples of four. It’s critical to be mindful of this number during your booklet layout to avoid having any unplanned booklet pages that are blank. The saddle stitch binding process occurs after printing the pages and cover, partially folding them and placing them together. After the staples join them , the cover and booklet pages should fold closer together. It’s possible for thicker saddle-stitched booklets to have trimming along the edge opposite to the spine to ensure page uniformity and a neat appearance. Booklets and other paper documents that commonly have saddle-stitched construction include wall calendars, newsletters, direct mailers, comic books, and thinner magazines.

The saddle stitching process method is the most effective for booklet binding and other publications with approximately 64 pages or less. Booklets that contain more pages run the risk of appearing bulky when folded and don’t lay flat during the saddle stitching process. When laying out the booklet pages, you must remember to use ample blank space (margins) surrounding the content of the pages. After binding a booklet, you should also avoid burying the print too deep in the crease of the booklet’s spine or near the edge. This way, you can avoid losing the content during the trimming process. The best way to prevent these errors is to check the digital printer or state of the manual saddle stapler in the early stages of booklet binding.

No matter what paper project you’re embarking on, you should assess what tools are appropriate for the job to avoid unnecessarily damaging materials. Ensuring success for your next stapling project requires a particular set of skills and the right tools to maximize them. That’s why knowing how to use a saddle stapler for booklet binding is vital. Staple Headquarters is proud to serve as your hub for industrial tools that meet the needs of all your business and DIY applications. Contact our expert team today for further information about our tools and project resources.