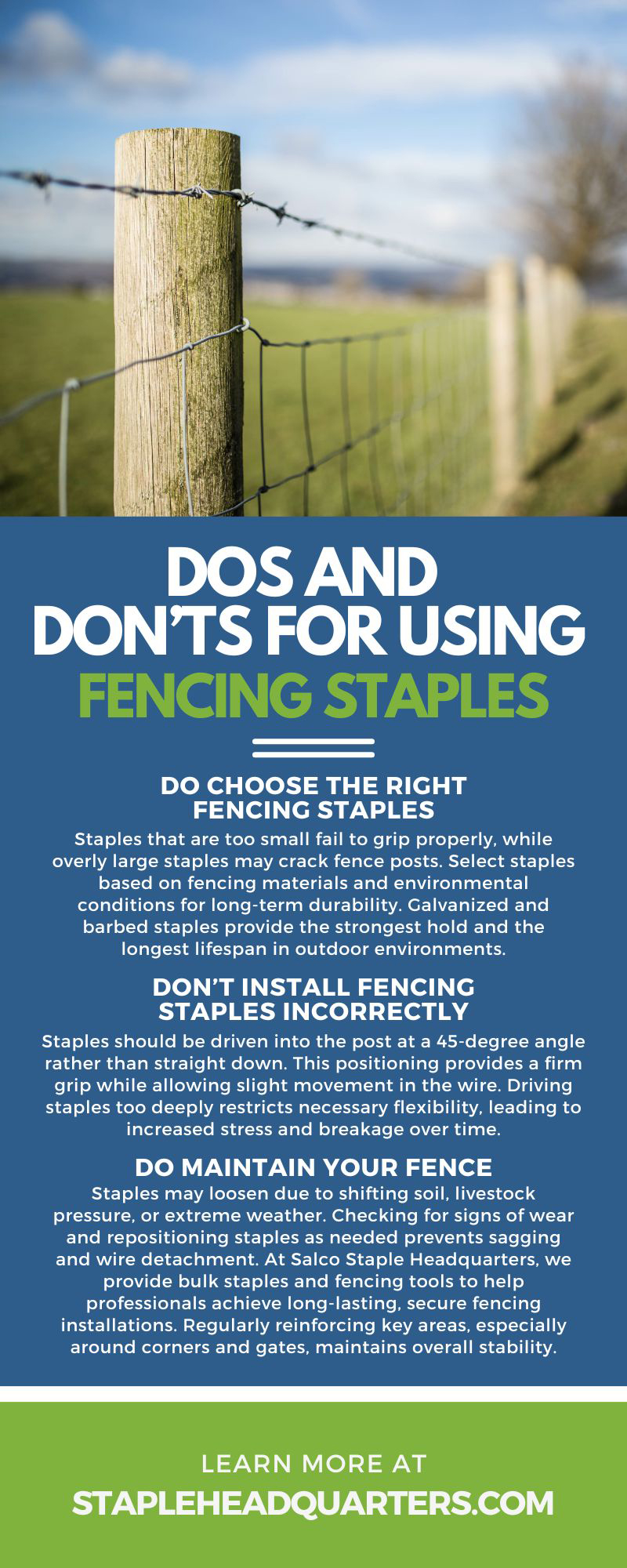

Fencing staples secure wire fencing to wooden posts, keeping fences strong, flexible, and long-lasting. Mistakes in staple selection or placement can lead to premature failure. These dos and don’ts for using fencing staples will help you prevent weak connections and unnecessary maintenance.

Do Choose the Right Fencing Staples

Staples that are too small fail to grip properly, while overly large staples may crack fence posts. Select staples based on fencing materials and environmental conditions for long-term durability. Galvanized and barbed staples provide the strongest hold and the longest lifespan in outdoor environments.

Picking the right staple improves the fence’s durability and reduces the need for repairs. Consider the following when choosing fencing staples:

Barbed Staples for Secure High-Tension Fencing

Barbed staples grip wooden posts tightly and provide the best hold for high-tension fencing like barbed wire or woven wire. The barbs along the staple legs dig into the wood to prevent movement and keep the staple from loosening over time. A more secure hold helps fences withstand strong winds and pressure from livestock.

Smooth Staples for Temporary or Adjustable Fencing

Smooth staples work well for fences that require easy removal or adjustments. Without barbs, they slide out easily and suit temporary enclosures or rotational grazing setups. Smooth staples also minimize damage to wooden posts when adjustments to the fence layout are necessary.

Galvanized Staples for Corrosion Resistance

Galvanized staples resist rust and corrosion due to their protective coating. Fences in humid or wet environments benefit from this added durability, as untreated staples tend to weaken over time. Using galvanized staples extends the lifespan of the fence and reduces the need for frequent replacements.

Longer Staples for Heavy-Duty Fence Installations

Longer staples, typically 1.5 to two inches, secure high-tensile wire and heavy-duty fencing. They penetrate deep into softer wood posts and provide a strong grip that prevents wire pullout. Proper angling during installation increases the staples’ holding strength for long-term stability.

Shorter Staples for Harder Posts or Thin Wires

Shorter staples, usually under 1.5 inches, secure thinner wires and work well in dense wood posts. These staples hold wires in place without splitting the wood and allow for easier adjustments when necessary. Smaller nails provide enough grip without unnecessary force.

Don’t Install Fencing Staples Incorrectly

The angle, depth, and spacing of each staple determine the overall strength and flexibility of the fence. Improper placement leads to wire damage, loose sections, and unnecessary stress on the fence posts.

Identifying issues early helps prevent long-term damage. Watch for common signs of installation problems. For example, staples pulling out too easily indicate incorrect sizing or shallow placement. Using staples that are too short or driving them in at the wrong angle prevents a secure hold. Selecting the right length and ensuring proper penetration into the post keeps the fence stable.

Staples should be driven into the post at a 45-degree angle rather than straight down. This positioning provides a firm grip while allowing slight movement in the wire. Driving staples too deeply restricts necessary flexibility, leading to increased stress and breakage over time.

Properly spaced staples allow for even distribution of tension, preventing weak points in the fence. Leaving a small gap between the staple and wire prevents excessive pressure, allowing for natural expansion and contraction.

Using a fencing hammer or staple gun designed for outdoor fencing provides consistent depth and prevents overdriving. Testing staple grip by gently pulling on the wire after installation confirms proper placement. A secure but flexible connection keeps the fence stable and long-lasting.

Do Maintain Your Fence

Proper maintenance keeps a fence stable over time, preventing common issues that arise from loose staples and shifting wire. Routine inspections and adjustments reduce the likelihood of costly repairs.

Staples may loosen due to shifting soil, livestock pressure, or extreme weather. Checking for signs of wear and repositioning staples as needed prevents sagging and wire detachment. At Salco Staple Headquarters, we provide bulk staples and fencing tools to help professionals achieve long-lasting, secure fencing installations. Regularly reinforcing key areas, especially around corners and gates, maintains overall stability.

Replace rusted or loose staples as soon as you notice them. You might also consider using additional support, such as brace posts at tension points, for greater durability. A well-maintained fence stands strong for years without requiring major repairs.

Ignoring loose staples can lead to fence sections pulling apart and increase the risk of injury to livestock or pets. Using mismatched staple sizes weakens certain areas, creating uneven tension that causes instability.

Do Adjust Staple Techniques for Different Fencing Materials

Fence material affects staple choice and installation methods. Wooden posts require a different approach than metal or composite alternatives. Using the same staple type for all fencing materials leads to weak connections and frequent adjustments. Staple penetration depth, angling, and spacing should be adjusted based on the specific fencing type.

Softwood posts allow for easy staple penetration but require longer staples for a secure hold. Hardwoods, such as oak, may cause splitting if staples are driven in too deeply, so predrilling pilot holes prevents damage. Metal posts typically require specialized fasteners instead of traditional staples for a tight grip on the wire.

Staple placement also varies depending on the fence type. Electric fencing requires loose stapling to avoid grounding the wire, while woven wire fencing benefits from tightly secured staples to maintain proper tension.

Properly installed fencing staples keep fences strong, flexible, and long-lasting. Choosing the right staple type, driving staples at the correct angle, and maintaining proper spacing improve fence durability. Regular maintenance prevents shifting, loose connections, and unnecessary repairs.

A well-secured fence withstands environmental stress and daily wear without frequent adjustments. Learning the dos and don’ts of fencing staples leads to a more efficient, reliable installation.

Explore our selection of staple tools and fencing solutions at Salco Staple Headquarters to complete your next fencing project with confidence.